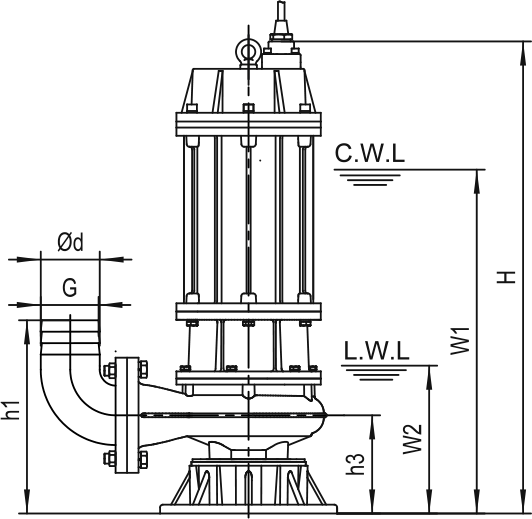

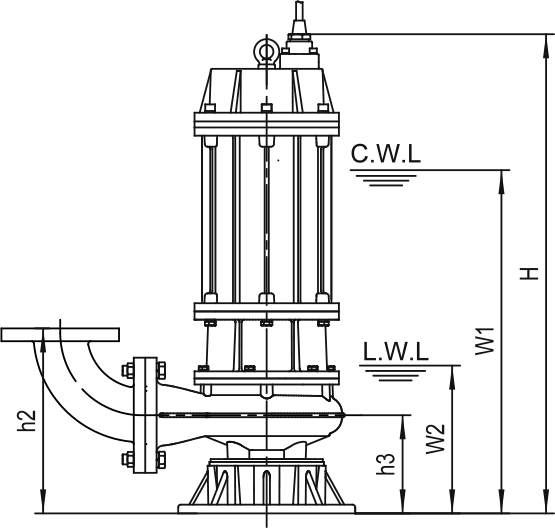

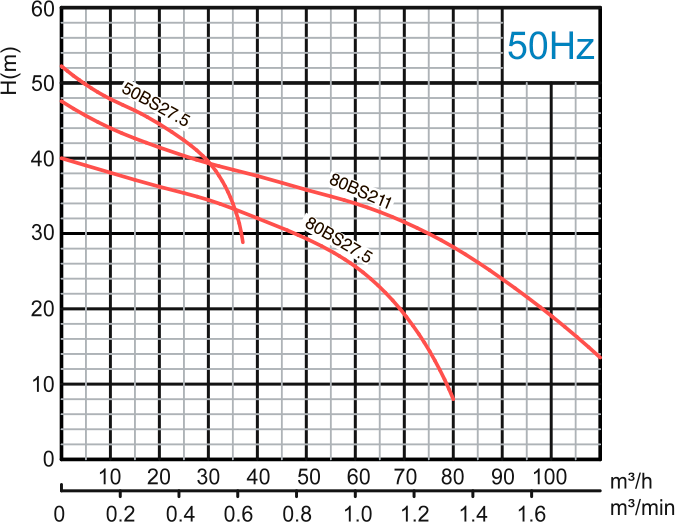

Solidpump BS-serie pompen bevatten een kanaalwaaier die speciaal is ontwikkeld voor afvalwaterpompen. De waaier heeft een breed kanaal dat zich uitstrekt van inlaat tot uitlaat, waardoor interne verstopping door vaste bestandsdelen die in de pomp worden gezogen, wordt voorkomen.

eng.png)