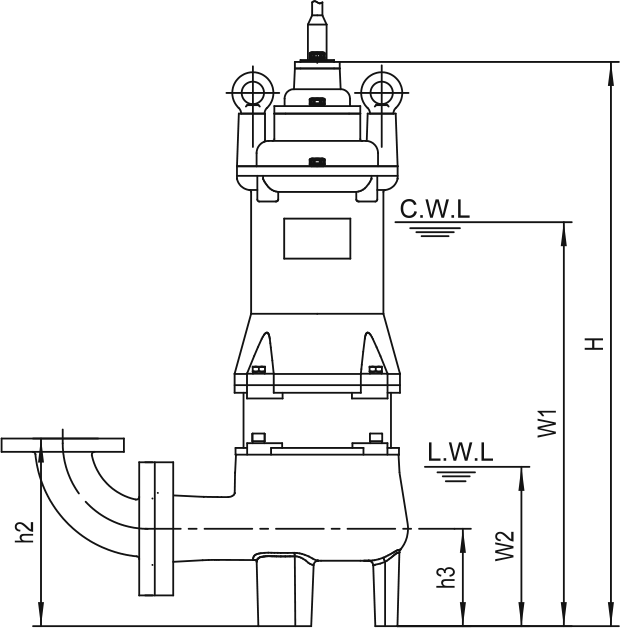

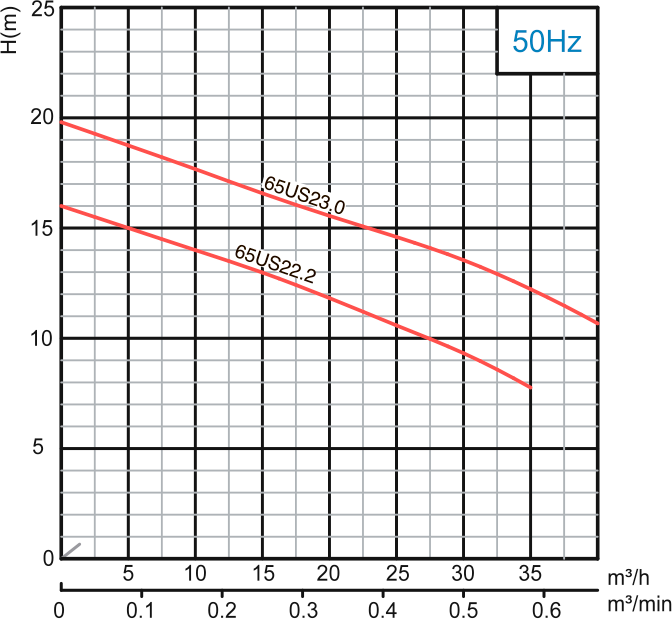

Solidpump US-serie pomp is een multifunctionele pomp met een vortexwaaier. De waaier die voornamelijk wordt gebruikt in Volute pompen. Vortex-waaiers genereren een krachtige wervelstroming die het water vanaf de inlaat naar de persaansluiting slingert, waardoor interne verstopping door vastebestandsdelen en vezelachtige stoffen wordt voorkomen.

eng.png)